At a glance:

- Choosing the right tyres is essential for ensuring the safety and performance of your vehicle.

- Consult the manufacturer’s recommendations or a trusted mechanic for a compatible tyre with your vehicle’s make and model.

- Whether you are a first-time tyre buyer or simply looking to upgrade your current set, read on to learn more.

Are you in the market for new tyres but feeling overwhelmed by the options available? Buying the right tyres can be a daunting task, but it is essential for ensuring the safety and performance of your vehicle. To make the process easier, there are several questions you should consider before making a purchase. We’ll discuss the important factors to take into account when purchasing new tyres in this blog article, giving you the knowledge you need to make an informed choice. So, whether you are a first-time tyre buyer or simply looking to upgrade your current set, read on to learn more.

ATV tyres

How do I determine the correct air pressure for my ATV tyres, and what are the consequences of over-inflating or under-inflating them?

The most common tyre pressure is 5-6 psi. That suits the average rider, on an average ATV, on average terrain. However, to determine the correct air pressure for your ATV tyres, refer to your ATV owner’s manual or check the manufacturer’s recommended tyre pressure. The control, stability, traction, and even tyre failure that can result from over- or under-inflation of your ATV tyres.

Are there any safety considerations I should keep in mind when selecting ATV tyres, such as reducing the risk of skidding or improving handling on steep terrain?

Safety considerations when selecting ATV tyres include choosing tyres that are appropriate for the type of terrain you’ll be riding on, such as selecting a tyre with aggressive treads for off-road use. Additionally, it’s crucial for safety to choose tyres with the proper load capability and speed rating.

What is the difference between bias-ply and radial-ply ATV tyres?

While radial-ply ATV tyres have cords that run parallel to the direction of movement, bias-ply ATV tyres are built with layers of cord material that are crisscrossed. Bias-ply tyres are generally less expensive, but radial-ply tyres offer better handling, ride comfort, and heat resistance. Depending on your riding style and the terrain you’ll be navigating, one option may not be the best fit for your requirements.

What are the pros and cons of different types of ATV tyre styles/ tread patterns?

Pros and cons of different types of ATV tyre treads:

Trail Tread:

Pros:

- Good for a wide variety of terrains, including dirt, gravel, and rocky trails.

- Provides good stability and traction on hard-pack surfaces.

- Can handle moderate mud and sand.

Cons:

- Not as effective in deep mud or snow as other treads.

- Can be loud and wear out faster on the pavement.

Mud Tread:

Pros:

- Designed for muddy and swampy terrain, with deep treads to provide maximum traction.

- Self-cleaning treads prevent mud build-up.

- Can also handle well in sand and loose dirt.

Cons:

- Not suitable for hard-pack or rocky surfaces.

- Can be heavy and more difficult to steer on harder surfaces.

- Can wear out faster on pavement.

Snow Tread:

Pros:

- Specially designed for snow and icy conditions, with deep treads and unique siping patterns to provide traction on slippery surfaces.

- Provides good floatation in deep snow.

Cons:

- Not ideal for other types of terrain.

- Can wear out quickly on hard-pack surfaces.

- May not provide enough traction in extreme ice conditions.

Race Tread:

Pros:

- Designed for high-speed racing on tracks and hard-pack surfaces.

- Lightweight and provides excellent traction and handling at high speeds.

- Good for sharp turns and acceleration.

Cons:

- Not suitable for muddy, rocky, or loose terrain.

- May wear out faster on rough terrain.

- Can be noisy and uncomfortable on long rides.

How can I assess the wear and tear on my existing ATV tyres, and when should I consider replacing them?

Assessing wear and tear on existing ATV tyres:

- Regularly check the tread depth because worn treads can decrease traction and raise the chance of an accident.

- Inspect the sidewalls for any cuts or fractures that might point to structural damage or deterioration of the tyre.

- If the tyres feel uneven or wobbly during riding, this may indicate uneven wear or other issues that require attention.

What are some common signs of ATV tyre damage or punctures, and how can I repair them if necessary?

Signs of ATV tyre damage or punctures:

- Visible cuts, tears, or punctures on the tyre’s surface.

- Loss of air pressure or changes in handling or stability during riding.

- Unusual noises or vibrations while riding.

How do I properly store my ATV tyres when they are not in use, and what are some best practices for keeping them in good condition?

Properly storing ATV tyres:

- Keep them in a cool, dry, and clean environment, away from direct sunlight or extreme temperatures.

- Store them away from any sources of heat, such as heaters or engines.

- If storing them for an extended period, consider removing them from the ATV and storing them upright or hanging them to prevent deformation

What kind of warranty or guarantee is available for ATV tyres, and what does it cover?

The terms and conditions of warranties can vary by manufacturer and seller, so it is important to read and understand them before purchasing. Warranties may cover defects in materials or workmanship but typically do not cover normal wear and tear, punctures, or damage caused by improper use or maintenance.

Are there any special considerations I should keep in mind when purchasing ATV tyres for use in specific climates or temperatures?

Some tyres are designed for use in specific conditions, such as snow or sand, and may perform poorly in other conditions. Consider the temperature range in which you will be riding and choose tyres that are rated for those conditions.

Quad Tyres

What size and type of tyre do I need for my quad bike, and how do I determine the right fitment?

The size and type of tyre required for your quad bike depend on various factors, such as the make and model of your vehicle, the type of terrain you’ll be riding on, and the weight of the rider and cargo. Consult the user manual for your quad bike or a qualified mechanic to ascertain the proper fitment.

What is the best type of tread pattern for quad bike tyres, and how does it affect performance on different terrains?

The best quad bike tyre tread pattern relies on the surface you’ll be riding on. For example, aggressive, deep-lugged tyres work best in muddy or sandy terrain, while shallow-lugged, widely spread tyres perform better on hard-packed surfaces.

What is the load capacity of quad bike tyres, and how does it impact the maximum weight you can carry?

The size and construction of quad bike tyres affect their load-carrying ability. To find out the most weight your quad bike tyres can safely carry, it’s critical to examine their load index rating. A quad bike that is overloaded may experience tyre failure, sloppy control, and diminished performance.

How often should you replace your quad bike tyres, and what is their expected lifespan?

Typically quad tyres last for 3-5 years. However, the use, maintenance, and storage of quad bike tyres all affect how long they will last. Regardless of mileage, you should generally change your quad bike tyres every three to four years. However, it is best to replace your tyres sooner if you detect signs of wear, cracking, or damage.

What are the top brands of quad bike tyres, and which ones are recommended for your specific needs?

In Australia, the leading manufacturers of quad bike tyres include Journey, Wanda, BKT, Kenda, Bushmate, Carlisle, and Maxxis. The right brand and model of tyres for your quad bike depend on your specific needs, such as the type of terrain you’ll be riding on and your riding style. Consult a professional mechanic or tyre specialist for expert advice on selecting the best quad bike tyres for your needs.

What are the key features to consider when selecting quad bike tyres, such as puncture resistance, durability, and grip?

Key characteristics to take into account when choosing quad bike tyres include puncture resilience, durability, grip, traction, and handling. Your unique requirements and riding style will determine the best combination of these features. For instance, if you plan to ride on rough territory, tyres that are durable, puncture-resistant, and have great traction are perfect.

How do you properly maintain and care for your quad bike tyres to ensure maximum longevity and performance?

The proper care and maintenance of your quad bike tyres are crucial to ensuring their optimum longevity and performance. This entails routinely checking them for wear, damage, or cracking, maintaining the recommended tyre pressure, cleaning them with mild soap and water on a regular basis, keeping them stored in a cool, dry location away from sunlight, and avoiding extended exposure to chemicals and oils.

What is the price range for quad bike tyres, and how much should you expect to spend for a quality set?

The name, size, and model all affect the quad bike tyre price range. A pair of high-quality quad bike tyres can cost anywhere between AUD 50 and AUD 300 or more per tyre. The best choice is to spend more money on high-quality tyres that are customised to your requirements and deliver the best performance.

Are there any safety considerations to keep in mind when purchasing new quad bike tyres, such as avoiding cheap or low-quality options?

Yes, when buying new quad bike tyres, there are a number of safety factors to bear in mind. First and foremost, it is crucial to refrain from purchasing inexpensive or inferior choices because these tyres might not have been produced in accordance with the necessary standards and could be dangerous. The performance and stability of the bike can be impacted by choosing tyres with a tread design that is appropriate for the terrain you will be riding on. Additionally, the load capacity of the tyres should match the weight of the rider and any cargo being carried.

Can you install new quad bike tyres yourself, or should you take your vehicle to a professional mechanic for installation and balancing?

It is typically advised to transport the vehicle to a qualified mechanic for installation and balancing when installing new quad-cycle tyres. This is due to the fact that fitting tyres can be a challenging task that calls for specialised tools and expertise. A poor installation can increase the chance of mishaps while also reducing stability and handling. A professional mechanic will ensure that the tyres are correctly installed and balanced, which will help to maximise their lifespan and performance.

Truck Tyre

What size and load capacity truck tyres do I need for my vehicle, and how do I determine the right fitment?

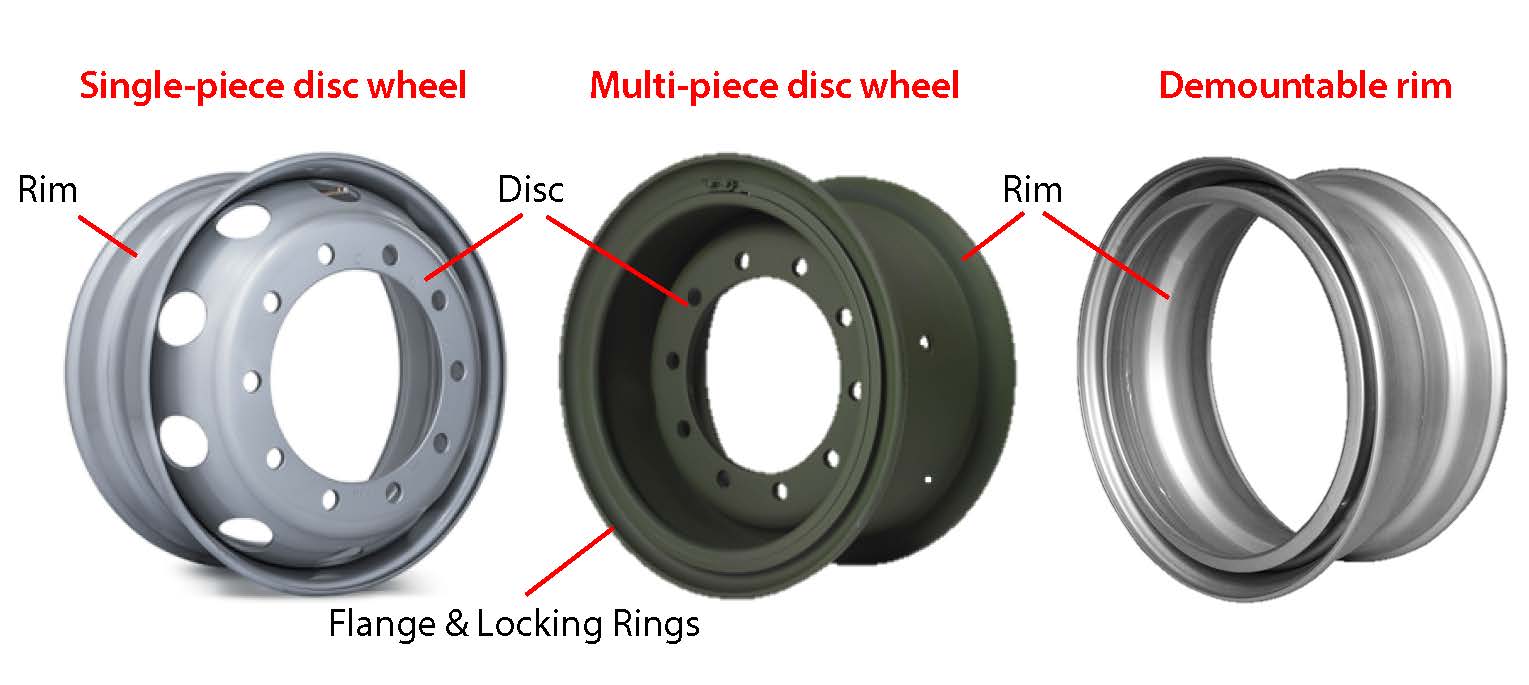

The size and load capacity of truck tyres needed for a particular vehicle will depend on the vehicle’s weight, load capacity, and the terrain it will be driven on. It is important to check the vehicle’s manual or consult a tyre professional to determine the correct size and load capacity. Fitment refers to the tyre’s ability to fit properly on the wheel rim and to match the vehicle’s specifications.

What is the best type of tread pattern for truck tyres, and how does it affect performance on different types of roads?

The best type of tread pattern for truck tyres depends on the type of road or terrain the vehicle will be driven on. Tread patterns are designed to provide grip and traction on different surfaces, such as wet or dry roads, gravel or mud.

For example, highway terrain tyres typically have less aggressive tread patterns for better fuel efficiency and a smoother ride, while all-terrain or mud-terrain tyres have deeper tread patterns for improved off-road performance.

What is the expected lifespan of truck tyres, and how often should you replace them?

The expected lifespan of truck tyres can vary depending on the tyre’s brand, usage, and maintenance. It is important to check the tyre’s wear regularly and replace them when the tread depth reaches 3mm or less, or when there is visible damage such as cuts or bulges.

What are the top brands of truck tyres, and which ones are recommended for your specific needs?

There are many top brands of truck tyres, including Windforce, Windpower, Triangle, Bridgestone, Kumho, Goodride, and Michelin, among others. The recommended brand and type of tyre will depend on the vehicle’s usage and specific needs. It is important to consult a tyre professional for recommendations based on the vehicle’s load capacity, driving conditions, and performance requirements.

What are the key features to consider when selecting truck tyres, such as rolling resistance, fuel efficiency, and grip?

When selecting truck tyres, key features to consider include rolling resistance, fuel efficiency, grip, load capacity, and durability. Rolling resistance refers to the amount of energy needed to keep the tyres rolling, while fuel efficiency is the tyre’s ability to conserve fuel. Grip is the tyre’s ability to provide traction on different surfaces, while load capacity refers to the maximum weight the tyre can safely carry. Durability is also an important factor to consider, as it can affect the tyre’s lifespan and overall performance.

How do you properly maintain and care for your truck tyres to ensure maximum longevity and performance?

Proper maintenance and care for truck tyres can help to ensure maximum longevity and performance. This includes regularly checking the tyre’s pressure, alignment, and balance, as well as rotating the tyres every 10.000 – 15,000 km. It is also important to avoid overloading the vehicle and driving on rough terrain or in extreme weather conditions.

Are there any safety considerations to keep in mind when purchasing new truck tyres, such as ensuring they meet industry standards for load and speed ratings?

Yes, safety considerations are important when purchasing new truck tyres. It is important to ensure that the tyres you purchase meet industry standards for load and speed ratings. The load capacity of the tyre should match the weight of the vehicle and the load it will carry. The speed rating of the tyre should match the maximum speed of the vehicle.

How do different types of truck tyres, such as all-terrain, highway, and mud-terrain, differ in terms of performance and suitability for different applications?

The range of truck tyres includes many different types, sizes and tread patterns. This makes sense, as truck tyres can be used for many different applications! When choosing the right truck tyre, you should take several factors into consideration: will long distances be driven? Or will it be short distances? Is the road surface flat? Or do you often drive on off-road terrain? Below I will explain a few applications and show you the tyre that can be used!

Interstate / Linehaul transport

Driving long distances at high speeds is an important factor in this type of transport. You need a tyre that has high wear resistance and offers excellent driving performance.

Regional and local transport

A typical feature of tyres used in regional and local transport is that they regularly accelerate and decelerate. These tyres cover fewer miles than interstate transport, but they must be safe and optimised for medium-haul operating conditions.

Intensive construction site

There are also truck tyres used as construction tyres. These tyres are specially designed to perform well on many different types of surfaces, such as wet and very dry surfaces. Normally will have Cut & Chip Resistant compound and heavier ply ratings.

On- and Off-Road

Finally, we have the truck tyres that are specially designed for use as both on- and off-road tyres. These tyres must perform on both muddy and sandy terrain.

Can you install new truck tyres yourself, or should you take your vehicle to a professional mechanic for installation and balancing?

It is recommended to have a professional mechanic install and balance new truck tyres. While it is possible to install the tyres yourself, it is important to ensure that they are balanced properly to prevent uneven wear and other potential safety issues. Improperly installed or balanced tyres can cause vibrations, steering problems, and other issues that can affect the handling and safety of your vehicle.

Mobile Crane

What size and load capacity mobile crane tyres do I need for my vehicle, and how do I determine the right fitment?

A complex procedure such as determining the size and load capacity of mobile crane tyres should be done in consultation with a tyre specialist. It involves considering factors such as the weight of the crane and the maximum weight it will be lifting, as well as the size and type of the crane’s axles.

What are the key features to consider when selecting mobile crane tyres, such as durability, heat resistance, and grip?

When selecting mobile crane tyres, it’s important to consider features such as durability, heat resistance, and grip.

Durability is important due to the heavy loads that mobile cranes typically carry, while heat resistance is significant due to the high temperatures generated by friction when the crane is in use. Grip is also critical, as mobile cranes often operate in rough terrain or in difficult weather conditions.

What are the top brands of mobile crane tyres, and which ones are recommended for your specific needs?

There are several top brands of mobile crane tyres, including Westlake, Goodride, Aeolus, Advance, Double coin, Michelin, Bridgestone, among others.

How do you properly maintain and care for your mobile crane tyres to ensure maximum longevity and performance?

Proper maintenance and care such as regular inspections, cleaning, and rotating the tyres to ensure even wear are essential for maximising the lifespan and performance of mobile crane tyres.

What are the different types of mobile crane tyres, and how do they differ in terms of performance and suitability for different applications?

Mobile crane tyres are designed for different applications, including truck-mounted cranes, rough terrain cranes, carry deck cranes and gantry cranes. Truck-mounted crane tyres have a sturdy construction and an all-terrain tread pattern for urban and suburban use. Rough terrain crane tyres have large, deep treads for stability on challenging surfaces. Carry deck crane tyres are smaller and more agile, with solid construction and a flat, smooth tread pattern. Gantry crane tyres have a wide, flat tread pattern and high load rating for heavy loads in industrial applications.

What are the safety considerations to keep in mind when purchasing new mobile crane tyres?

Safety considerations when purchasing mobile crane tyres include ensuring they meet industry standards for load and speed ratings, as well as ensuring they are compatible with your crane’s specific axles and suspension system.

Can you install new mobile crane tyres yourself, or should you take your vehicle to a professional mechanic for installation?

Due to the complex and potentially dangerous nature of mobile cranes, it’s recommended to have new tyres installed by a professional mechanic with experience working on mobile cranes. This will help ensure proper fitment and installation.

What are some common issues or challenges that can arise with mobile crane tyres?

Common challenges with mobile crane tyres include wear and tear, overloading, inadequate inflation, improper storage, incompatible tyres, and uneven wear. Regular maintenance and inspections can help prevent these issues and ensure optimal performance and safety.

OTR

What are OTR tyres, and what types of vehicles or equipment are they typically used on?

Off-The-Road (OTR) tyres are designed for use on heavy-duty equipment and vehicles that operate in rough terrain, such as mines, quarries, construction sites, and ports. Some common vehicles and equipment that use OTR tyres include dump trucks, bulldozers, wheel loaders, and cranes.

What is the best type of tread pattern for OTR tyres, and how does it affect performance on different types of terrain?

The best tread pattern for OTR tyres depends on the specific application and terrain conditions. There are several different tread patterns available, such as ribbed, lug, and block patterns. Ribbed patterns are best suited for hard, smooth surfaces, while lug and block patterns provide better traction on soft, loose surfaces like mud or sand. Some OTR tyres also have directional treads that are designed for a specific forward or backward motion.

What is the expected lifespan of OTR tyres, and how often should you replace them?

The expected lifespan of OTR tyres varies depending on factors such as usage, load capacity, and maintenance. Generally, OTR tyres can last between 3,000 to 10,000 hours of operation or more. It’s recommended to regularly inspect OTR tyres for signs of wear and damage and replace them when the tread depth reaches a minimum safe level.

What are the top brands of OTR tyres, and which ones are recommended for your specific needs?

Some of the top brands of OTR tyres include, Aeolus, Windpower, Advance, Triangle, BKT, Bridgestone, Michelin, Henan among others The best brand and model for your specific needs depend on your equipment and the conditions you will be operating in.

What are the key features to consider when selecting OTR tyres?

When selecting OTR tyres, it’s important to consider factors such as load capacity, durability, traction, heat resistance, and puncture resistance. Load capacity refers to the amount of weight the tyre can safely support, while durability and puncture resistance are important for ensuring the tyre can withstand rough terrain conditions.

What are some common issues or challenges that can arise with OTR tyres, and how can you address them to maintain optimal performance and safety?

Common issues or challenges that can arise with OTR tyres include uneven wear, punctures, cuts, and damage from debris or harsh environments. Proper maintenance and care for OTR tyres include regularly inspecting them for signs of wear and damage, maintaining proper inflation levels, rotating tyres, and ensuring they are properly aligned. Keeping tyres clean and free from debris can also help prolong their lifespan. Suitable storage and maintenance can also help to extend the lifespan of OTR tyres and ensure maximum performance.

What is the price range for OTR tyres, and how much should you expect to spend for a quality set?

The price range for OTR tyres can vary depending on the brand, size, and specific application. Generally, OTR tyres are more expensive than passenger or light truck tyres and can range from a few hundred to several thousand dollars per tyre.

What are the safety considerations to keep in mind when purchasing new OTR tyres?

When purchasing new OTR tyres, it’s essential to ensure they meet industry standards for load and speed ratings. It’s also important to consider the specific application and terrain conditions to ensure the tyre can provide adequate traction and durability.

Can I install a new OTR tyre or take it to a professional mechanic for installation?

This typically requires specialised equipment and expertise. So, it’s recommended to have a professional mechanic handle the installation of OTR tyres to ensure proper fitment and performance.