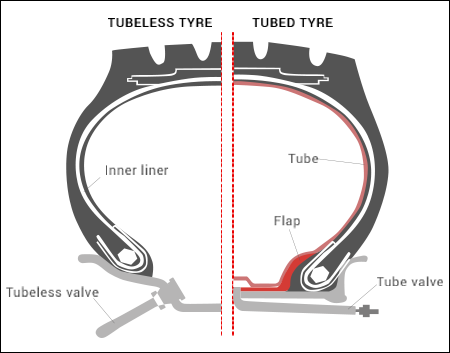

Pneumatic tyres come in two main types: Tube-Type (TT) and Tubeless (TL).

Because tyre rubber is naturally porous, an extra layer is required to keep the assembly air-tight and maintain the seal between the tyre and the rim.

If this air-tight liner is a separate piece with its own valve – an Inner Tube – then the tyre is said to be Tube-Type (TT).

If the air-tight liner is built into the tyre, which is far more common on modern or high-speed tyres, then the tyre is Tubeless (TL) because an inner tube is not required.

TUBE-TYPE (TT) TYRES

Of the two tyre types (TT and TL), tyres with an inner tube are a more traditional option. In this case, the inner tube – which has its own valve – is placed inside the tyre.

Due to the limits for radial and total flexibility identified for each tyre, the inner tube must fit perfectly inside the carcass.

If the inner tube is too big, it may fold and result in premature failure. If the inner tube is too small, it could be over-stretched and thus increase the likelihood of tearing and decrease the quality of the seal.

If these tyres are punctured, it is cheaper to replace the inner tube rather than the whole (tubeless) tyre.

The risks and areas of focus when using inner tubes are as follows:

Incorrect size of tube (and/or flap if present).

Increased heat from friction between tyre and tube.

Sudden loss of air pressure if the tube is punctured.

Exposed inner tube if a tyre is damaged, leading to sudden tube failure.

Possible requirement for rim tape or flap to protect the tube.

TUBELESS (TL) TYRES

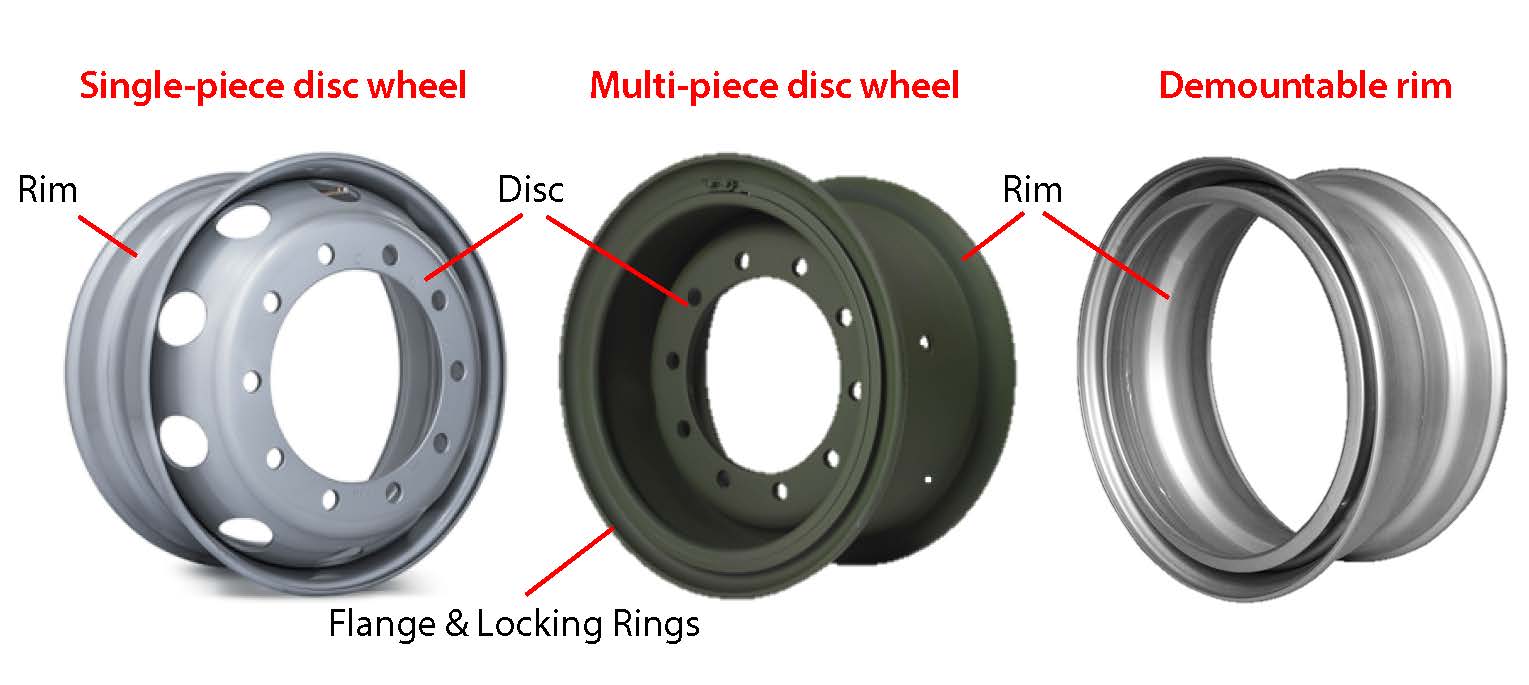

Tubeless tyres fit perfectly against the special elevated edge (hump) of tubeless wheel rims, which helps to create an air-tight seal.

This means special inner edges and rim tape are not needed. The valve has been incorporated into the wheel rim and features a special rubber seal.

These tyres are so compact – in terms of the carcass and rubber composition – that no, or only minute amounts of air can escape via the pores.

One of the advantages of tubeless tyres is that they lose air gradually if there is a leak in the carcass – caused by, for example, a nail.

As a result, vehicle handling will also decrease gradually, which helps to improve safety.

Punctures can often be repaired by placing a tyre plaster on the inside of the carcass, or via vulcanization in case of severe damage.

Contact the team at Oceanic Direct to assist you with any questions or to help your conversion to tubeless tyres on off the shelf wheels and rims.